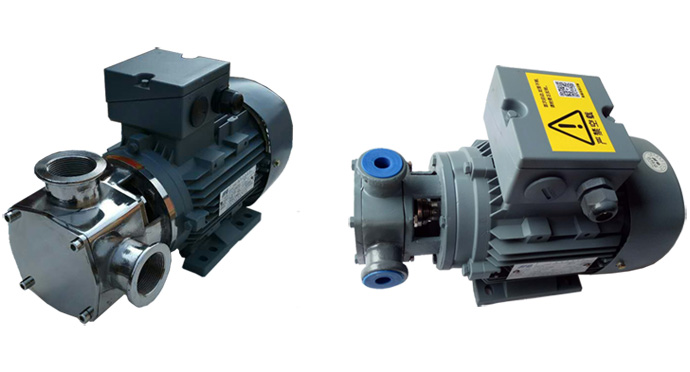

Flexible rotor pump (RXB) is widely used in a variety of substitutes, strong self-priming, large flow, small size, low cost performance, known as energy saving pump.

Product performance:

1, strong self-suction, perfect structure principle, dry self-priming 6 meters, with material with material self-priming 9 meters

2, short self-priming time, instant self-priming within 6 meters,2-3 seconds to complete.

3, simple structure, easy maintenance, do not need professional guidance, maintenance does not need to remove the pump pipe.

4, one purchase pump lifetime use, less wearing parts.

5, small size occupies small space of field equipment.

6, large flow high efficiency, the same flow power is small and more energy saving.

7, indoor installation without noise

8, can transport hard particles containing particle impurities.

9. The viscosity of the conveying medium can reach 5000 cm

Working principle

① There is an eccentric convex block in the pump cavity. When the flexible blade leaves the eccentric block, the volume between the blades continues to increase, resulting in a vacuum, which makes the liquid continuously sucked into the inlet of the pump cavity.

② When the flexible blade rotates, the liquid is brought into the discharge part by the suction part of the pump chamber.

③ When the flexible blade contacts the eccentric convex block again, it bends, and is accompanied by an extrusion action, so that the liquid is discharged from the pump chamber uninterrupted and without pulsation, thus completing the whole process of suction and discharge.

As the core technology of flexible pump, the impeller of the pump should have good elasticity, small deformation, and can withstand long and high frequency flexure without breaking and tearing. "Ten years of grinding a sword", the excellent impeller elastomer technology determines the excellent performance and durability of the pump. There are two kinds of impeller materials - health grade nitrile rubber, EPDM; Nitrile impellers are mainly used in vegetable oil, mineral oil, oil-containing media and areas with high health requirements; Ethylene propylene wheel is mainly used in weak inorganic acid, organic acid, alkali, salt, alcohol, ketone, sewage and other wide range of media.

Features:

Small size, large flow rate - In general, smaller volume at the same flow rate compared to competitive pumps. Easy to install and move.

Instant complete self-priming - no additional device required, no fluid replenishment before starting. Suction range up to five meters.

The pump body is made of stainless steel precision casting, and all the over-flow gold components are stainless steel (1Cr18Ni9Ti).

The viscosity of the conveying medium can reach 2000 cm

It can transport gas-containing liquid and foam liquid without gas resistance

It can transport medium containing suspended soft and hard particles.

The gentle action of the rotor does not damage the shear sensitive media, such as paper dispersants.

When the flexible rotor is running, there is no metal contact and no spark. With explosion-proof motor especially suitable for alcohol, gasoline, acetone and other solvents transport.

Beautiful appearance, durable, easy maintenance

Applications:

The excellent self-priming performance and strong working condition adaptability of the pump make it used in a variety of industrial occasions, for bucket pouring, bin sweeping, underground tank liquid suction and drainage, sampling and a variety of fluids, semi-fluid transportation, such as pouring the barrel only need to insert the import hose into the barrel can be drained suction static. Widely replaced centrifugal self-priming pump, hydraulic pump, gear pump, single screw pump and other pumps.

Chemical industry - weak inorganic acids, organic acids, bases, salts, oils, alcohols, ketones, esters and other media

Flexible rotor pump specifications and parameters

| specification | Rated lift (m) | Rated flow (m3/h) | Motor (KW) | Speed (r/min) | Power Supply (v) | caliber |

| 15-RXB | 30 | 1 | 0.37(normal/explosion-proof) | 1400 | 380/220V | Four points |

| 20-RXB | 30 | 2 | 0.55(normal/explosion-proof) | 1400 | 380/220V | 6 points |

| 25-RXB | 30 | 5 | 0.75(Normal/explosion-proof) | 1400 | 380/220V | 1 inch |

| 40-RXB | 30 | 12 | 1.5(General/explosion-proof) | 1400 | 380/220V | 1.5 inch |

| 50-RXB | 30 | 18 | 3(Normal/explosion-proof) | 1400 | 380V | Two inches |

PREVIOUS: 3RP CAM rotor pump