QWP type stainless steel submersible sewage pump product overview

QWP stainless steel submersible sewage pump is the introduction of foreign advanced experience in high efficiency and energy saving sewage pump without plugging, combined with the technical strength of the unit developed, the performance indicators have reached the national standard level of similar products. Due to the use of unique single channel impeller, dynamic seal using two groups of special materials cemented carbide mechanical seal device. The motor oil chamber is separated, with no blockage, high efficiency, significant energy saving, is a new product of pump upgrading in our country, and is welcomed and praised by users.

The advantages of the pump can transport sewage containing solid particles and containing fiber materials, without blocking and entangling. It is suitable for transporting industrial wastewater and urban sewage, and can also be used as drainage pump, pulp pump, washing condensate circulation pump through filtration, irrigation pump and other sewage treatment occasions can also be used for pumping water. QW submersible type is especially suitable for frequent movement or temporary emergency occasions, without fixed installation, set the rubber tube, connect the pipe and put the pump into the bottom.

QWP type stainless steel submersible sewage pump product features

① The unique single blade or double blade impeller structure greatly improves the dirt passing capacity, and can effectively pass 5 times the fiber material and solid particles with a diameter of about 50% of the pump diameter.

② The mechanical seal uses a new type of hard corrosion-resistant tungsten carbide material, and the seal is improved to a double-end seal, so that it can run in the oil chamber for a long time, which can make the pump run safely and continuously for more than 8000 hours.

The overall structure is compact, small volume, low noise, significant energy saving effect, easy maintenance, no need to build a pump room, diving into the water can work, greatly reducing the project cost.

④ The sealing oil chamber of the pump is equipped with a high-precision anti-interference water leakage detection sensor, and the stator winding is embedded with a thermal element to protect the pump motor ****.

⑤ Can be equipped with automatic safety protection control cabinet according to user needs, the pump water leakage, leakage, overload and overtemperature **** protection, improve product safety and reliability.

The float switch can automatically control the start and stop of the pump according to the required liquid changes, without special care, and it is very convenient to use.

7 Can be equipped with double rail automatic coupling installation system according to user needs, it brings great convenience to installation and maintenance, people can not enter the sewage pit for this.

⑧ Can be used in the full head range, while ensuring that the motor will not overload.

There are two different installation methods, fixed automatic coupling installation system, mobile free installation system.

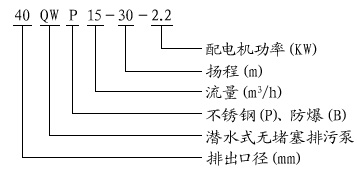

QWP type stainless steel explosion-proof submersible sewage pump model significance

QWP type stainless steel submersible sewage pump performance parameters

| Model number | caliber | Flow rate | head | power | Rotational speed | efficiency |

| mm | m3/h | m | KW | r/min | % | |

| The 25-8-22-1.1 - | 25 | 8 | 22 | 1.1 | 2900 | 38.5 |

| The 32-12-15-1.1 - | 32 | 12 | 15 | 1.1 | 2900 | 40 |

| 40-15-15-1.5 | 40 | 15 | 15 | 1.5 | 2900 | 45.1 |

| 40-15-30-2.2 | 40 | 15 | 30 | 2.2 | 2900 | 48 |

| 50-20-7-0.75 | 50 | 20 | 7 | 0.75 | 2900 | 54 |

| The 50-10-10-0.75 - | 50 | 10 | 10 | 0.75 | 2900 | 56 |

| 50-20-15-1.5 | 50 | 20 | 15 | 1.5 | 2900 | 55 |

| 50-15-25 to 2.2 | 50 | 15 | 25 | 2.2 | 2900 | 56 |

| 25-20-50-2.2 | 50 | 25 | 20 | 2.2 | 2900 | 56 |

| 18-30-50-3 | 50 | 18 | 30 | 3 | 2900 | 58 |

| 50-25-32-5.5 | 50 | 25 | 32 | 5.5 | 2900 | 53 |

| 50-20-40-7.5 | 50 | 20 | 40 | 7.5 | 2900 | 55 |

| 65-25-15-2.2 | 65 | 25 | 15 | 2.2 | 2900 | 52 |

| 65-37-13-3 | 65 | 37 | 13 | 3 | 2900 | 55 |

| 65-25-30-4 | 65 | 25 | 30 | 4 | 2900 | 58 |

| 65-30-40-7.5 | 65 | 30 | 40 | 7.5 | 2900 | 56 |

| 65-35-50-11 | 65 | 35 | 50 | 11 | 2900 | 60 |

| 65-35-60-15 | 65 | 35 | 60 | 15 | 2900 | 63 |

| The 80-40-7-2. 2 | 80 | 40 | 7 | 2.2 | 1450 | 52 |

| 43-13-80-3 | 80 | 43 | 13 | 3 | 2900 | 50 |

| 40-15-80-4 | 80 | 40 | 15 | 4 | 2900 | 57 |

| 80-65-25-7.5 | 80 | 65 | 25 | 7.5 | 2900 | 56 |

| The 100-80-10-4 | 100 | 80 | 10 | 4 | 1450 | 62 |

| The 100-110-10-5. 5 | 100 | 110 | 10 | 5.5 | 1450 | 66 |

| 100-100-15-7.5 | 100 | 100 | 15 | 7.5 | 1450 | 67 |

| 100-80-20-7.5 | 100 | 80 | 20 | 7.5 | 1450 | 68 |

| 100-100-25-11 | 100 | 100 | 25 | 11 | 1450 | 65 |

| 100-100-30 to 15 | 100 | 100 | 30 | 15 | 1450 | 66 |

| 100-100-35-18.5 | 100 | 100 | 35 | 18.5 | 1450 | 65 |

| 125-100-15-11 | 125 | 100 | 15 | 11 | 1450 | 62 |

| 125-130-20-15 | 125 | 130 | 20 | 15 | 1450 | 63 |

| The 150-145-9-7. 5 | 150 | 145 | 9 | 7.5 | 1450 | 63 |

| 150-180-15-15 | 150 | 180 | 15 | 15 | 1450 | 65 |

| 150-180-20-18.5 | 150 | 180 | 20 | 18.5 | 1450 | 75 |

| 150-180-25 to 22 | 150 | 180 | 25 | 22 | 1450 | 76 |

| 150-130-30-22 | 150 | 130 | 30 | 22 | 1450 | 75 |

| 150-180-30-30 | 150 | 180 | 30 | 30 | 1450 | 73 |

| 150-200-30 to 37 | 150 | 200 | 30 | 37 | 1450 | 70 |

| 150-160-45-37 | 150 | 160 | 37 | 37 | 1450 | 70 |

| The 200-300-7-11 | 200 | 300 | 7 | 11 | 980 | 73 |

| The 200-250-11-15 | 200 | 250 | 11 | 15 | 980 | 74 |

| 200-250-15-18.5 | 200 | 250 | 15 | 18.5 | 1450 | 72 |

| The 200-400-10-22 | 200 | 400 | 10 | 22 | 1450 | 76 |

| 200-400-13-30 | 200 | 400 | 13 | 30 | 1450 | 73 |

| 200-300-15-22 | 200 | 300 | 15 | 22 | 1450 | 73 |

| 200-250-22-30 | 200 | 250 | 22 | 30 | 1450 | 71 |

| 200-350-25-37 | 200 | 350 | 25 | 37 | 1450 | 75 |

| 200-400-30 to 55 | 200 | 400 | 30 | 55 | 1450 | 70 |

| The 250-600-9-30 | 250 | 600 | 9 | 30 | 980 | 74 |

| 250-7 600-12-3 | 250 | 600 | 12 | 37 | 1450 | 78 |

| 250-600-15-55 | 250 | 600 | 15 | 55 | 1450 | 75 |

| 250-600-20 and 55 | 250 | 600 | 20 | 55 | 1450 | 73 |

| 300-500-15-45 | 300 | 500 | 15 | 45 | 980 | 70 |

| 300-800-15-55 | 300 | 800 | 15 | 55 | 980 | 73 |

| 300-600-20 and 55 | 300 | 600 | 20 | 55 | 980 | 75 |

| 300-800-20-75 | 300 | 800 | 20 | 75 | 980 | 78 |

| 300-950-20-90 | 300 | 950 | 20 | 90 | 980 | 80 |

| 300-1000-25-110 | 300 | 1000 | 25 | 110 | 980 | 82 |

| 350-1100-10-5 | 350 | 1100 | 10 | 55 | 980 | 84.5 |

| 350-1500-15-90 | 350 | 1500 | 15 | 90 | 980 | 82.5 |

| 350-1200-18-90 | 350 | 1200 | 18 | 90 | 980 | 83.1 |

| 350-1100-28-132 | 350 | 1100 | 28 | 132 | 740 | 83.2 |

| 350-1000-36-160 | 350 | 1000 | 36 | 160 | 740 | 78.5 |

| 400-2000-15-132 | 400 | 2000 | 15 | 132 | 740 | 85.5 |

| 400-1700-22-160 | 400 | 1700 | 22 | 160 | 740 | 82.1 |

| 400-1500-26-160 | 400 | 1500 | 26 | 160 | 740 | 83.5 |

| 400-1700-30-200 | 400 | 1700 | 30 | 200 | 740 | 83.5 |

| 400-1800-32-250 | 400 | 1800 | 32 | 250 | 740 | 82.1 |

| 500-2500-10-11 | 500 | 2500 | 10 | 110 | 740 | 82 |

| 500-2600-15-160 | 500 | 2600 | 15 | 160 | 740 | 83 |

| 500-2400-22-220 | 500 | 2400 | 22 | 220 | 740 | 84 |

| 500-2600-24-250 | 500 | 2600 | 24 | 250 | 740 | 82 |