Diaphragm pumps are positive displacement pumps that have become increasingly popular in industrial applications due to their versatility, reliability, and ability to handle a wide range of fluids. Unlike traditional centrifugal pumps, diaphragm pumps use a flexible diaphragm to move fluid, providing a unique solution for transferring liquids and gases in situations where other pumps might fail. These pumps excel in applications that require precise flow control, resistance to dry running, and the ability to handle abrasive or corrosive materials.

What is a Diaphragm Pump?

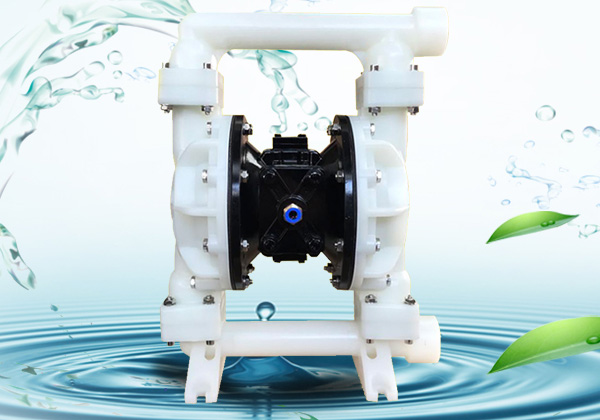

A diaphragm pump operates using a flexible diaphragm that alternately flexes in and out to create suction and discharge pressure. This pumping action is achieved by mechanical or air-driven mechanisms, which push and pull the diaphragm to transfer the fluid. The main advantage of diaphragm pumps is their ability to handle a broad spectrum of fluids, from water to highly viscous and aggressive liquids, without contamination. Their self-priming nature and ability to run dry without damage make them particularly useful in challenging conditions.

Industry Applications of Diaphragm Pumps

Chemical and Pharmaceutical Industries Diaphragm pumps are widely used in the chemical and pharmaceutical industries, where precise control and safe transfer of hazardous or viscous fluids are essential. These pumps are ideal for transferring chemicals, acids, solvents, and other aggressive substances. In pharmaceutical production, diaphragm pumps are used to handle delicate ingredients, as they provide a contamination-free transfer, ensuring the purity and quality of sensitive compounds.

Water and Wastewater Treatment In water and wastewater treatment plants, diaphragm pumps play a vital role in the transportation of sludge, chemicals, and other treatment agents. These pumps are used to transfer coagulants, flocculants, and chlorine without any risk of contamination. The diaphragm pump’s ability to operate in harsh conditions with minimal maintenance makes it a preferred choice for ensuring smooth operations in water treatment facilities.

Food and Beverage Processing The food and beverage industry requires pumps that can handle food-grade liquids while maintaining strict hygiene standards. Diaphragm pumps are commonly used to transfer dairy products, sauces, juices, and other food ingredients. Because diaphragm pumps can be easily cleaned and sanitized, they are ideal for applications that require frequent cleaning cycles, ensuring that production stays free of contamination while maintaining the integrity of the product.

Oil and Gas Industry In the oil and gas industry, diaphragm pumps are used in drilling, transfer, and chemical injection applications. These pumps can handle various fluids, including crude oil, drilling mud, and additives used in the extraction process. Their ability to transfer abrasive and highly viscous fluids makes them well-suited for environments where traditional pumps might be ineffective. Additionally, diaphragm pumps can operate under high pressures, making them ideal for pipeline transfer and injection operations in oil fields.

Mining and Mineral Processing Diaphragm pumps are employed in the mining industry to transfer slurries, which consist of water mixed with ore particles, chemicals, or other processing agents. The abrasive nature of slurries demands a robust pump capable of withstanding wear and tear. Diaphragm pumps are ideal for this application due to their durability and ability to maintain a consistent flow while handling high solid content without clogging.

Printing and Coatings In industries such as printing, painting, and coatings, diaphragm pumps are used to transfer inks, dyes, and various liquid coatings. These pumps are capable of delivering precise amounts of fluid and are ideal for applications where fluid viscosity can vary significantly. Diaphragm pumps provide consistent flow and pressure, ensuring smooth and even application in printing and coating processes.

Shanghai Lanhai Pumps: Leading the Way in Diaphragm Pump Technology

Shanghai Lanhai Pumps is a trusted manufacturer that provides high-quality diaphragm pumps for a range of industrial applications. The company is known for its cutting-edge pump technologies and has developed a variety of diaphragm pump solutions that meet the demanding needs of sectors such as chemicals, pharmaceuticals, food processing, and water treatment.

Lanhai Pumps are designed for versatility, durability, and easy maintenance, which makes them an excellent choice for industries with high operational demands. Their diaphragm pumps can handle a wide range of fluids—both clean and abrasive—while ensuring precise flow control and minimal downtime. Shanghai Lanhai Pumps uses top-grade materials and advanced engineering to ensure their diaphragm pumps deliver reliable performance in the most challenging environments.

With a commitment to innovation and customer satisfaction, Shanghai Lanhai Pumps continues to provide industry-leading diaphragm pump solutions that help businesses optimize their fluid transfer processes.

Conclusion

Diaphragm pumps are invaluable in a wide variety of industries due to their ability to handle difficult fluids, provide precise flow control, and operate under harsh conditions. From chemical processing to food production, mining, and wastewater treatment, these pumps deliver reliable performance where other pumps might struggle. With manufacturers like Shanghai Lanhai Pumps offering high-quality, durable diaphragm pumps, industries can count on a solution that meets their specific needs while ensuring efficiency and safety.

PREVIOUS: The Essential Role of Pipeline Pumps in Modern Industry

NEXT:No previous